As an OEM company, we work together with our customers on their product design needs as well as develop both new and innovative products within the industry. From this collaboration, we offer feedback on improvements to provide the best in-class solutions for our customers. The Tech O.E.M. team is well-versed in resolving issues and taking initiative to fix product-related issues efficiently for our customers.

While more and more manufacturers are emphasizing on the “Green” program for purposes to benefit both the environment and end-users, Tech O.E.M. has made a continuous effort throughout its time within the industry. Not only does this benefit the end users, but producing environmental-friendly items give us a competitive advantage as one of the greatest valves within the industry.

Tech O.E.M.'s team of experienced engineers collaborate with customers to develop new products specifically for their needs. Combining our drawing and product development capabilities along with the IAPMO test lab facility, we can ensure highest quality and safety of newly developed items.

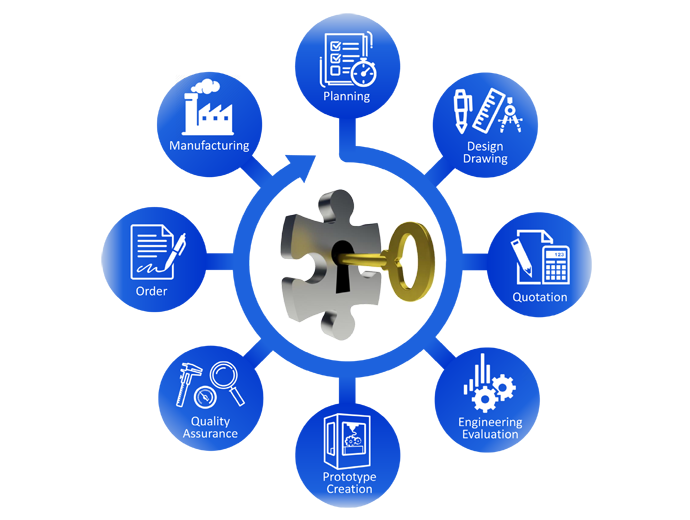

Every new product follows our extensive product development system. Periodic reviews are conducted frequently until the customers offer their final approval.

New product ideas, can be quickly changed into physical samples and rigorously tested in the Tech O.E.M. in-house IAPMO lab. This allows us to quickly evaluate design elements and apply the necessary changes.